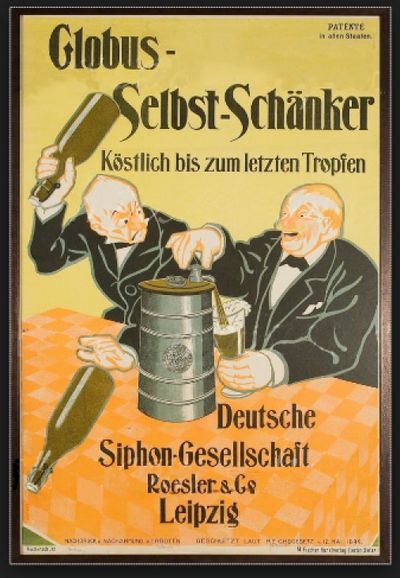

Roesler Globus Selbst-Schanker Bier Siphon

Brewing History

All good things have a history. Treasuring and learning from our past brewing history is at the heart of Roesler & Company Brewing, focusing on the process and ingredients to brew the best traditional German Beers.

Der Bier Siphon

Beer for the House

Even in the Middle Ages, beer was transported in wooden barrels and tapped into drinking vessels. The carbon dioxide present in the beer and gravity caused the beer to flow. The tap had to be located at the bottom of the barrel.

Since around the middle of the 19th century, attempts have been made to increase the pressure in the barrel by pumping in air. The tap could now be attached above for a more convenient tap. There were various pumping devices for this.

The disadvantage, however, was the harmful effect of atmospheric oxygen on the beer.

Only with the invention of the liquefaction of carbonic acid (M. Faraday, 1823) and the industrial use for CO2-containing drinks (Wilhelm C. Raydt, 1880) were beer dispensers in the inns and home dispensers technically possible.

The dispensing technology in the inns changed fundamentally in the 1890’s.

At this time, beer kegs were connected to a carbonated bottle both in the pub and in the private household. Due to the counter pressure, the beer-own carbon dioxide was retained for a longer time, which significantly extended the freshness.

The disadvantage for home use, however, was that a relatively large and heavy carbon dioxide bottle was required.

The siphons were larger in the Kaiser's time, intended for 10 or 5 liters of beer. The emptying was carried out comfortably by the pressure of the carbon dioxide supplied via a metal tap, which was arranged at the top of the siphon head.

The siphons were made of glass, metal or earthenware.

In the 1890s, they were connected to a carbon dioxide bottle. Advertising "The siphon beer is fresh as on tap".

A further development of the German Siphon Society from Berlin led to the "Siphon Perfect", which was offered in 1897/1898. With this patented system, the glass siphon filled with beer stood in a metal container.

The Leipzig Company Roesler brought out a completely closed metal container in 1896/97 under the name: "Globus Selbstschänker". The inner glass container was designed for 10 liters of beer. The tap was operated via a turntable, which was removable and was intended to prevent unauthorized use.

This new dispenser was introduced in 1897 at the Saxon-Thuringian industrial and commercial exhibition. This robust system has been used in many countries for over 30 years.There were two different types of metal siphons offered, Can Form or Barrel Shape. Examples from Roesler & Co. from Leipzig, founded in 1896.

At that time, these home dispensers were filled with beer, aerated and delivered to the house. There were also accessories for refilling the siphon with beer from a barrel and adding carbon dioxide again. The outer metal body was made of pure nickel. The inner vessel, filled with beer, was made of glass or enamel. The beer was therefore not in contact with the metal. It reached the tap located above via a glass tube.]

Many specimens were lost in the war due to melting or destruction.

Beer siphon advertising on advertising stamps and on a postcard

Brewing Relics

.png/:/rs=w:370,cg:true,m)

Roesler & Company Brewing

La Crosse, Wisconsin

Copyright © 2019 Roesler & Company Brewing - All Rights Reserved